Bringing all medical device components to the next generation

Polishing technology specialized for fine holes

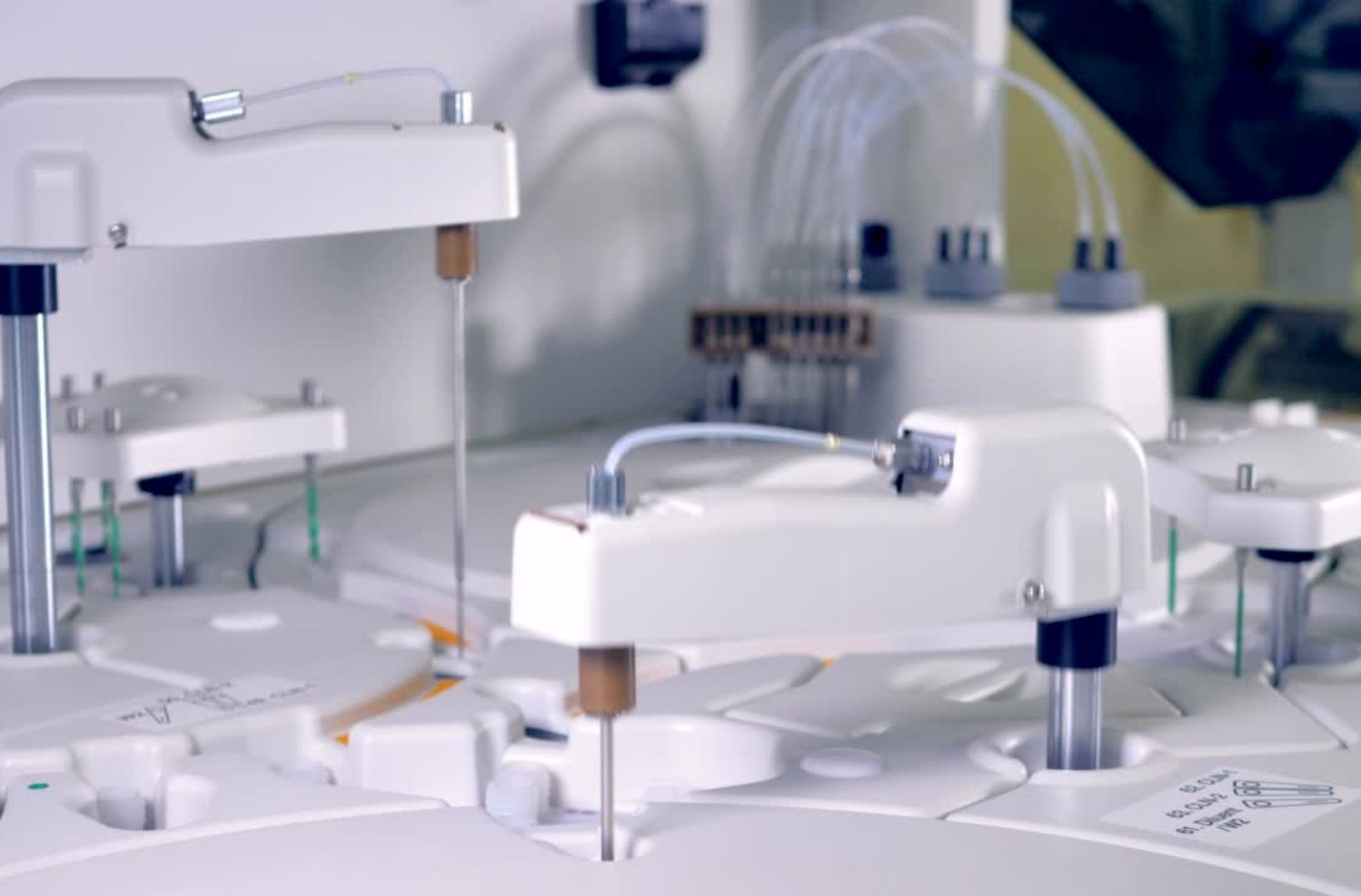

Applying and developing our expertise in fine hole polishing in other fields for the past 8 years, we have been polishing metal tubes and nozzles, deburring and dross removal.

Extensive polishing experience

Medical device parts

stent

catheter

Bio-cellular liquid injection needle

Nozzles for analysis and inspection

Supported range

Inner diameter: Φ0.1 to Φ4mm (Φ10 will be supported in the future)

Total length: 10 to 2000mm

Surface roughness: Ra0.01 or less is available (please consult us)

Material: Ni/Ti, Co/Cr, SUS, Ti, etc.

Dross removal, oxide film removal, mirror polishing finish, and dimensional cross-adjustment are all completed in one process.

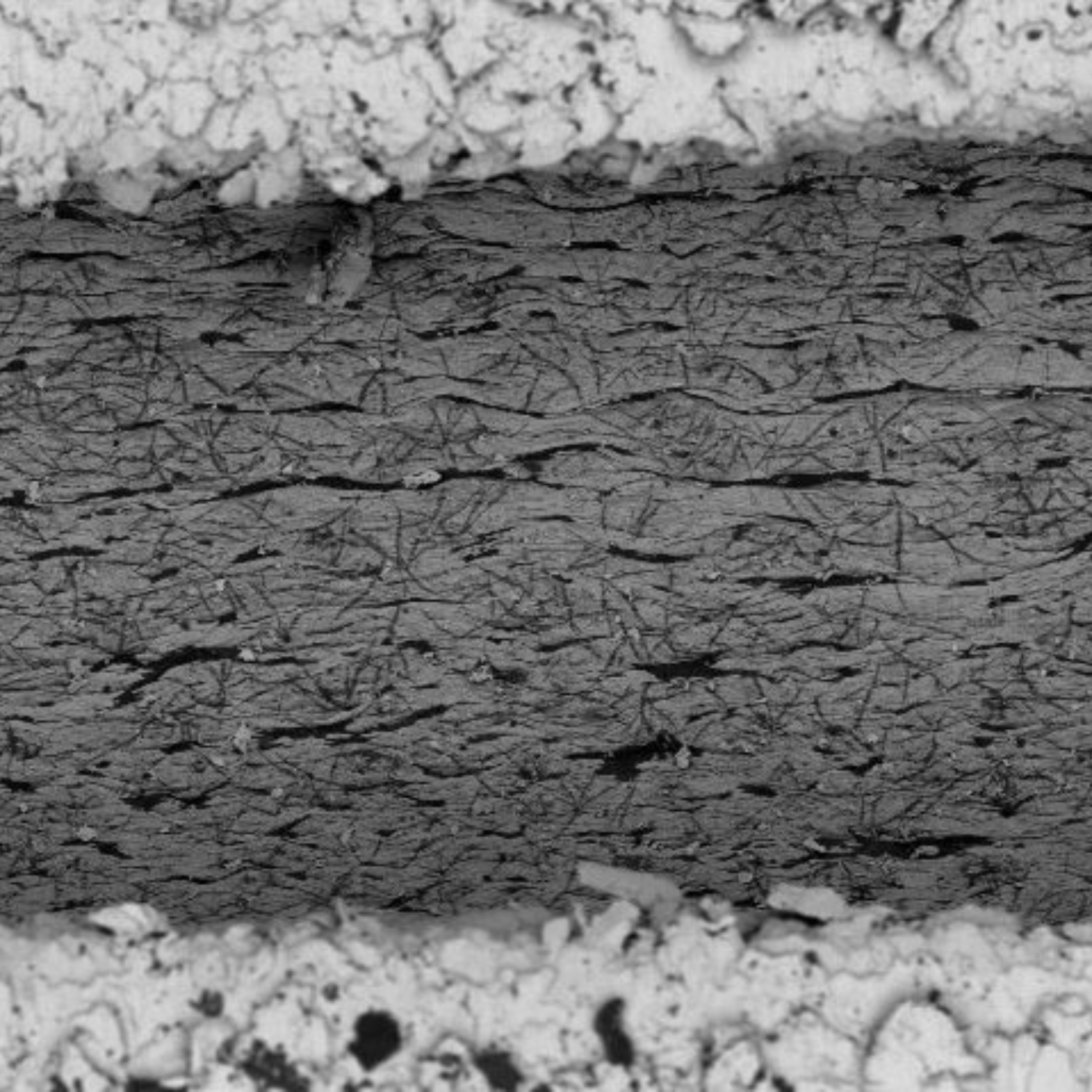

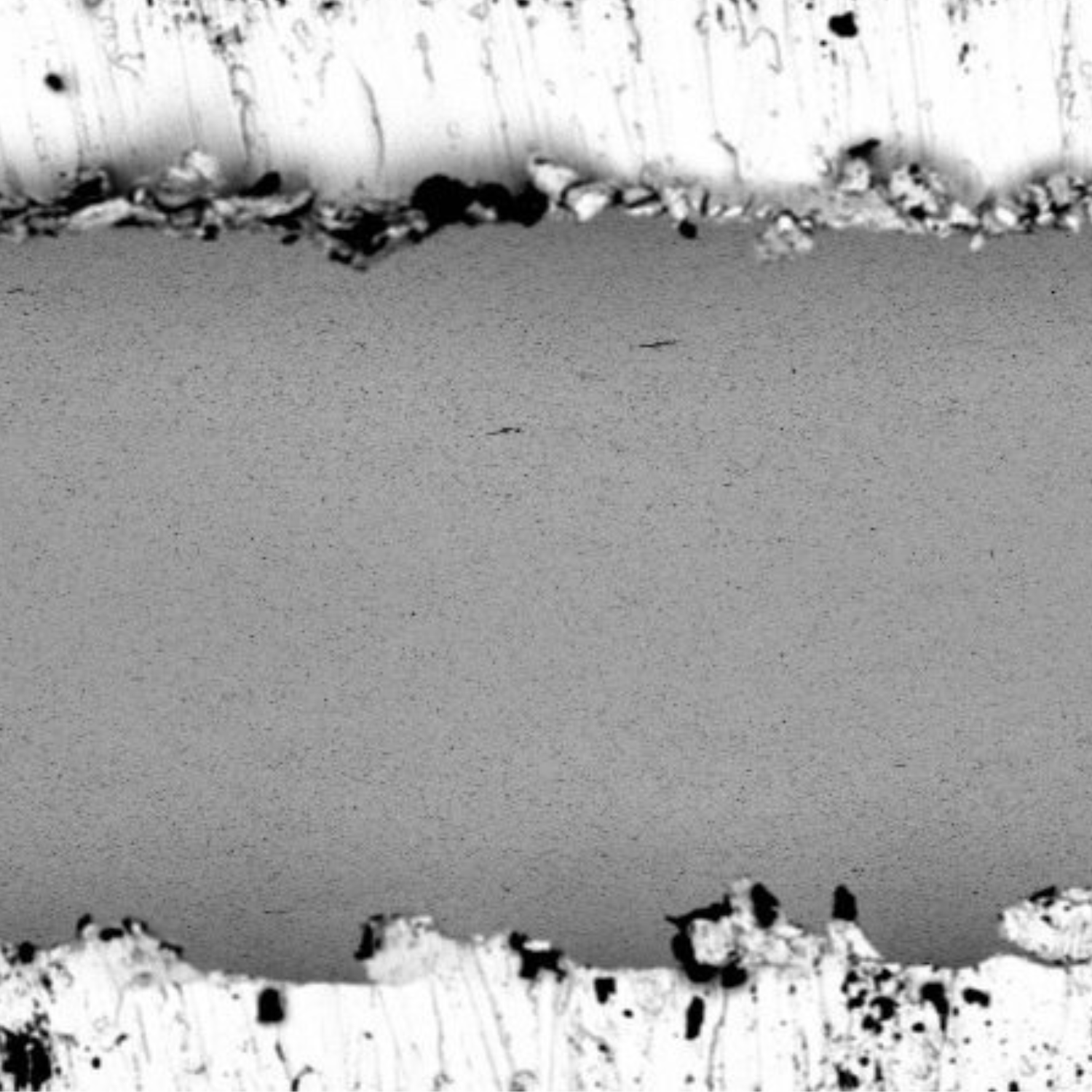

mirroring

Ra0.736

↓

Ra0.07μm

Parts: Medical Pipes

← Slide while tapping the center bar →

Slide while tapping the center bar

← →

A major advantage you gain by letting us handle your project.

Offers great potential for medical device components

added value

The mirror surface enables a constant volume of suction and injection, which improves the quality of medical fluid testing.

time reduction

Superior polishing power shortens polishing time compared to other companies’ polishing methods.

cost reduction

Easy-to-operate, fully automated management reduces labor costs and increases production efficiency.

eco-friendly

Uses only water and abrasives, no chemical solvents, and environmentally friendly low running costs.