We can do it.

Eco-friendly polishing

Friendly to both people and the environment We create the future of polishing.

スムーズにご注文いただく為に、ご注文書の項目にパーツコード(旧表記:機種名、Ref.No.、パーツNo. )を必須で記載いただきますようお願い申し上げます。

例)MT8_PEEK_JR-T-6004-M10 PEEKチューブ内径φ1.59 10m

大変お手数おかけ致しますが、ご注文時の相違を無くし、スムーズな取引になりますよう

ご協力をお願い申し上げます。

アルゴヴィジョンは進化します。

2025年1月より装置製造販売から受託研磨事業へ

-装置販売の受付期間-

弊社は本年から受託研磨事業を推進し

新規での装置販売は行わない方向性となりました。

しかしながら装置販売停止までには移行期間を設け

その期間を本年12月末までとさせていただきます。

体制の変更に伴いご迷惑をおかけいたしますが

何卒ご理解のほど宜しくお願い申し上げます。

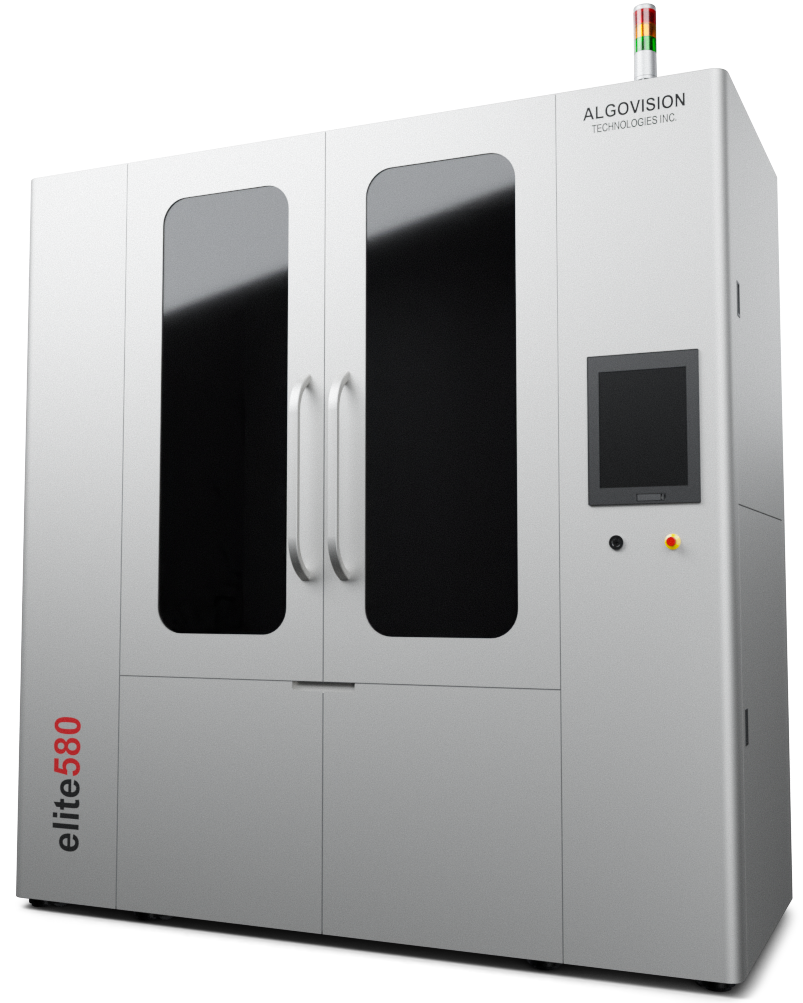

Algovision evolves.

From January 2025, the Company will shift from equipment manufacturing and sales to contract polishing business.

-Acceptance period for equipment sales-

Starting this year, we will be promoting our contract polishing business

and will no longer be selling new equipment.

However, there will be a transition period before we stop selling equipment, and this period will run until the end of December this year.

We apologize for any inconvenience caused by this change in structure,

and we appreciate your understanding.

Algovision is

Evolution.

From January 2025, the Company will shift from equipment manufacturing and sales to contract polishing business.

-Acceptance period for equipment sales-

We have decided to promote our contract polishing business from this year and will not sell any new equipment. However, we will have a transition period until the end of December of this year before we stop selling equipment. We apologize for any inconvenience this change may cause and ask for your understanding.

アルゴヴィジョンは

進化します。

2025年1月より装置製造販売から

受託研磨事業へ

-装置販売の受付期間-

弊社は本年から受託研磨事業を推進し、新規での装置販売は行わない方向性となりました。しかしながら装置販売停止までには移行期間を設け、その期間を本年12月末までとさせていただきます。体制の変更に伴いご迷惑をおかけいたしますが、何卒ご理解のほど宜しくお願い申し上げます。

下記のボタンよりPDFファイルを開いてブラウザから保存ください。

Pickling is not necessary with Algovision’s polishing equipment.

The excellent polishing power of high-speed flowing water and abrasive particles enables completion of dross, removal of oxide film, mirror finishing, and dimensional crossing in a single process. No pickling reduces the impact on the global environment. It is also possible to reduce the gas generated by waste water, which adversely affects the surrounding environment and workers’ health.

Thank you for your inquiry.

We have sent you an auto-reply e-mail.

Our representative will reply to you within a few days.

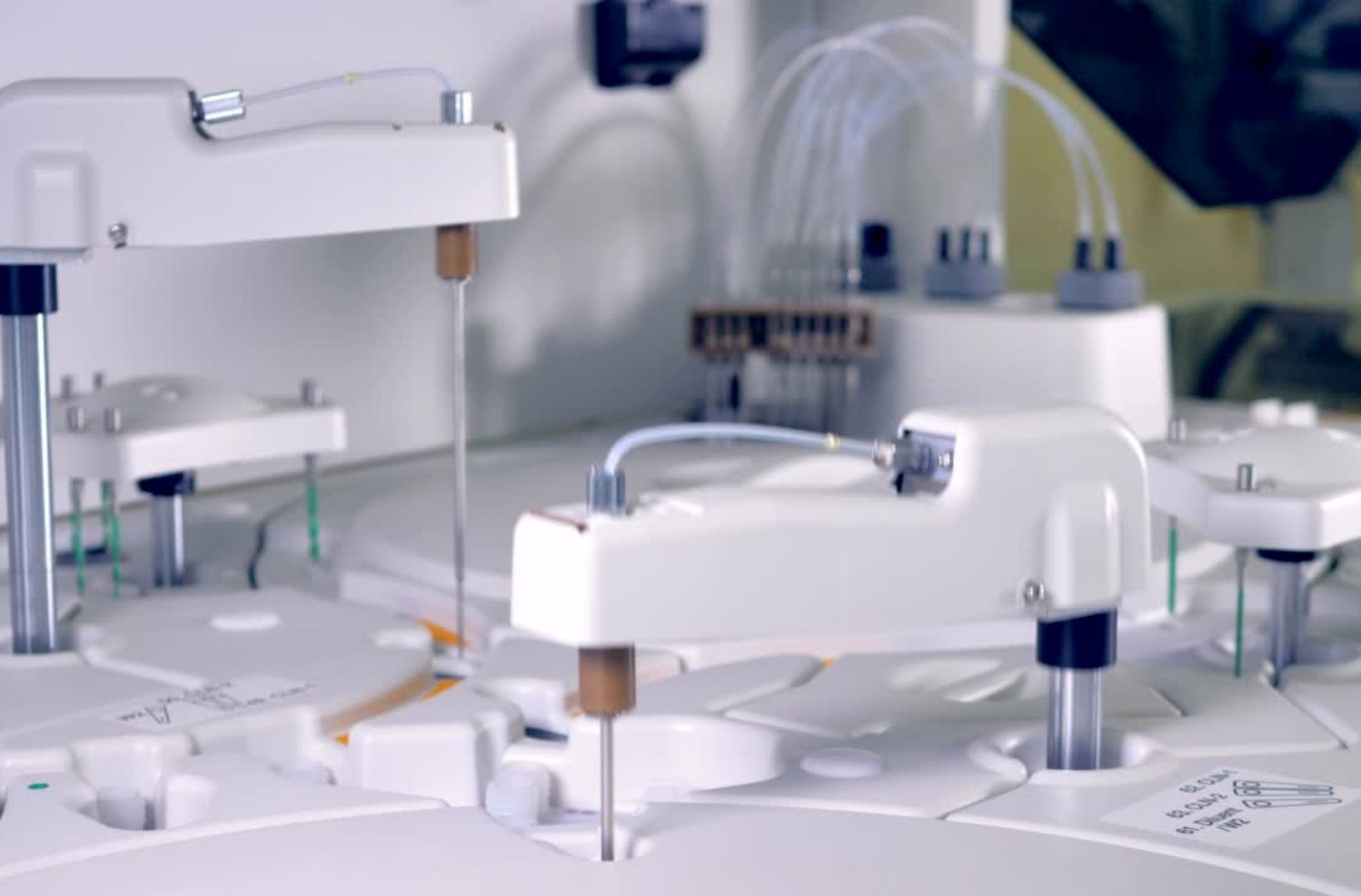

This is a technical device that efficiently polishes workpieces in a short time by adjusting the flow rate, pressure, and time of slurry mixed only with water and abrasives flowing in one direction.

Hazardous chemical agents and expensive diamonds are not used. The abrasive particles used are inorganic materials, which are relatively inexpensive and environmentally friendly. The polishing action is a simple and easy technology that utilizes physics and does not have a complicated structure.

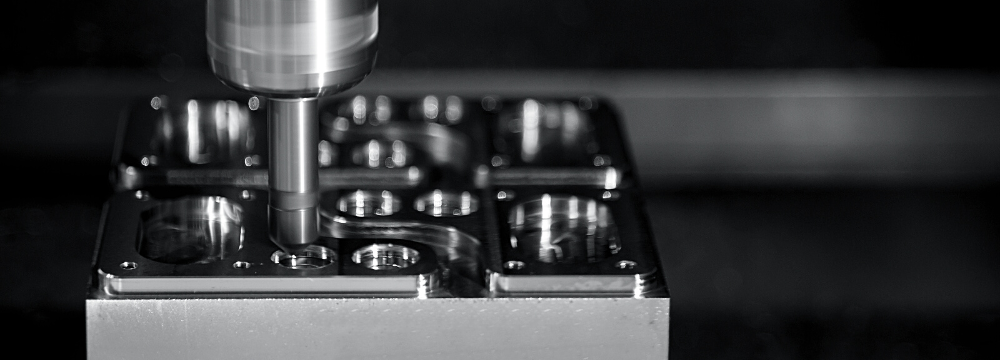

Our fluid polishing technology was originally developed to remove the melted and resolidified layer (also known as the machining alteration layer/white layer) after WEDM and EDM processing of cemented carbide molds and steel-based resin molds such as SKD material.

Initially developed as a “composite fluid polishing” technology that combines oxidation treatment and fluid polishing technology for melting and resolidifying layers, the process technology has been further developed to enable mirror polishing.

It is now possible to easily remove the molten and resolidified layer in 5 to 15 minutes without oxidation treatment. The slurry used does not contain expensive diamond particles, but inexpensive hard mineral materials that are readily available on the market, dispersed and mixed in tap water, making the equipment easy for anyone to handle, with low running costs.

We also provide technical consulting services to remove the molten/resolidified layer (work alteration layer/white layer).

そもそも当社の流体研磨技術は、超硬合金金型やSKD材などのスチール系樹脂成形金型のWEDM,EDM加工後の溶融再凝固層 (加工変質層/白層とも呼ばれる)を除去する目的で開発されました。

当初は、 溶融再凝固層を酸化処理と流体研磨技術とを合わせた”複合流体研磨”技術として開発されたものであり、その技術を更に鏡面研磨が可能となるようにプロセス技術の開発を進めてきたものです。

現在は、酸化処理をしないで5~15分で簡単に溶融再凝固層を除去することが可能になりました。使用するスラリーは、高価なダイヤモンド粒子を使用せず、市場で手に入りやすい安価な硬質鉱物系材を水道水に分散混合して使用することでランニングコストも抑えた、誰でも扱い易い装置になっております。

溶融再凝固層 (加工変質層/白層)を除去するための技術コンサルティングも行っております。

Algovisionの研磨装置で酸洗は不要。

高速で流れる水と砥粒子による優れた研磨力でドロス、酸化被膜の除去、鏡面仕上げ、寸法交差まで1工程で完了させることができます。酸洗をしないことで、地球環境への影響が軽減できます。排水で発生するガスの近隣環境への影響、作業者の健康面への影響など様々な影響を軽減できます。

水+研磨材のみを混ぜたスラリーを一方向に流し流量・圧力・時間を

調節することによりワークを効率的に短時間で研磨する技術装置です。

危険な化学用剤、高価なダイヤモンドなどは使わず。使用する砥粒子も比較的安価で

環境にもやさしい無機物系材料を使用。研磨作用も物理を利用した単純で簡単な技術であり

複雑な構造ではありません。