“CONCEPT”

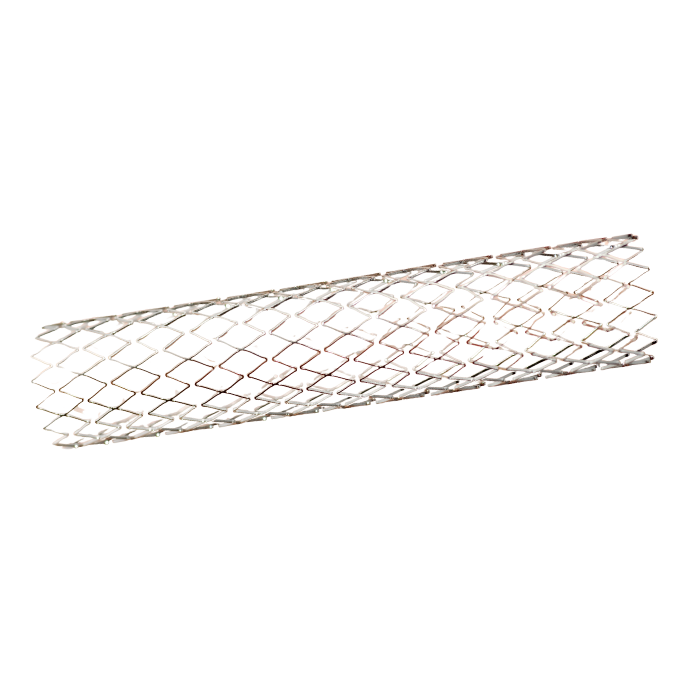

Invisible finishes that support life.

Surfaces of medical devices are the invisible contact points of life. It should be smooth. That alone keeps blood undisturbed, bacteria from attaching, and even reduces pain. A difference of just a few microns determines the accuracy and safety of treatment. Our polishing is not just a finishing touch. It is a job to set the boundaries of whether or not the patient’s body can comfortably fit into it. There is a difference that cannot be seen but can certainly be felt. Invisible finishes that support life. We polish with a precision that is trusted the moment you touch it.

MATERIAL PROTECTION

The sustainable nature of the process, which uses only water and abrasives, reduces the hazards of chemicals and hydrogen embrittlement, which have been problems in stent manufacturing to date. It also contributes to improved production takt time by reducing processing time. Because it is something that is put into the human body, we are committed to providing safer and better options.

PURSUIT OF QUALITY

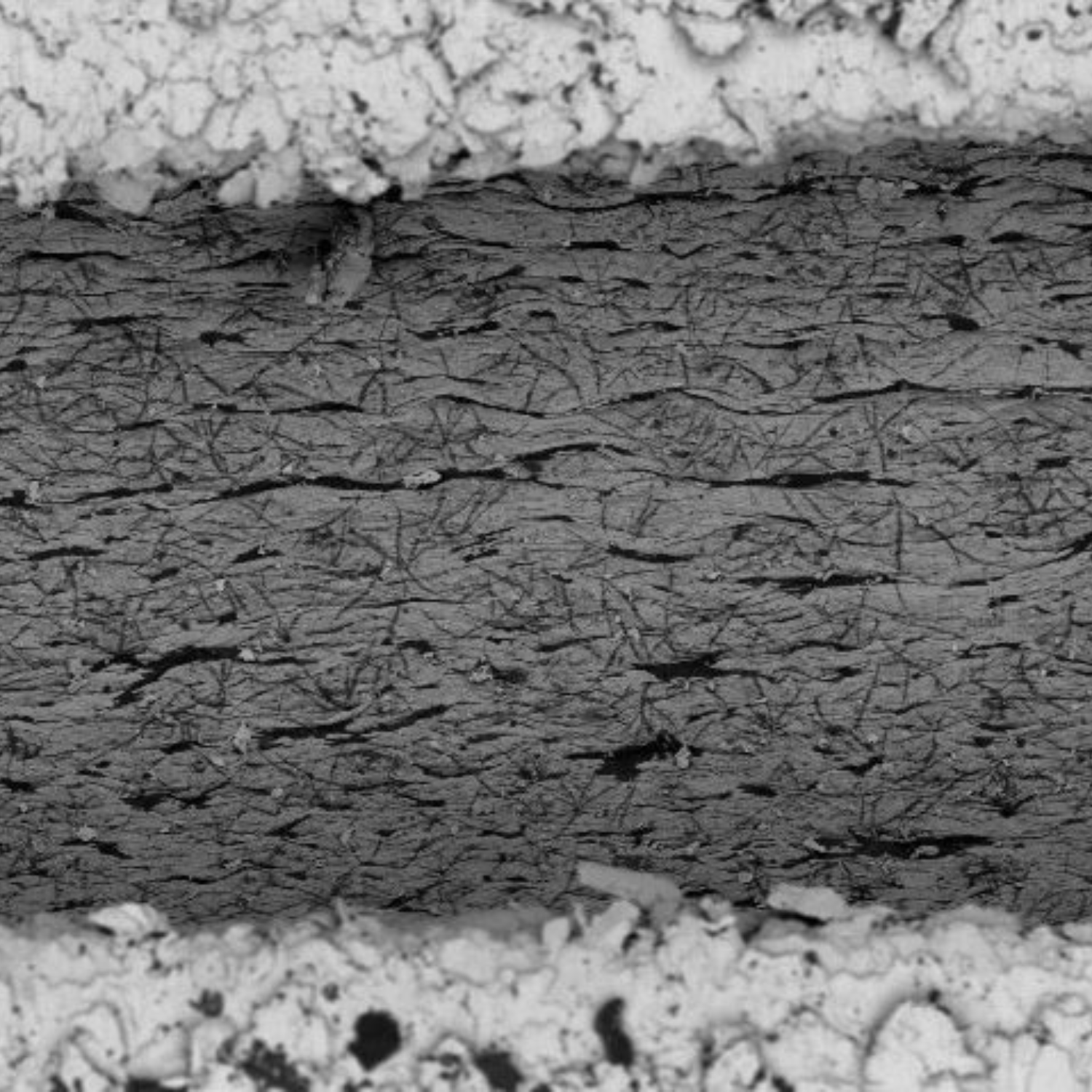

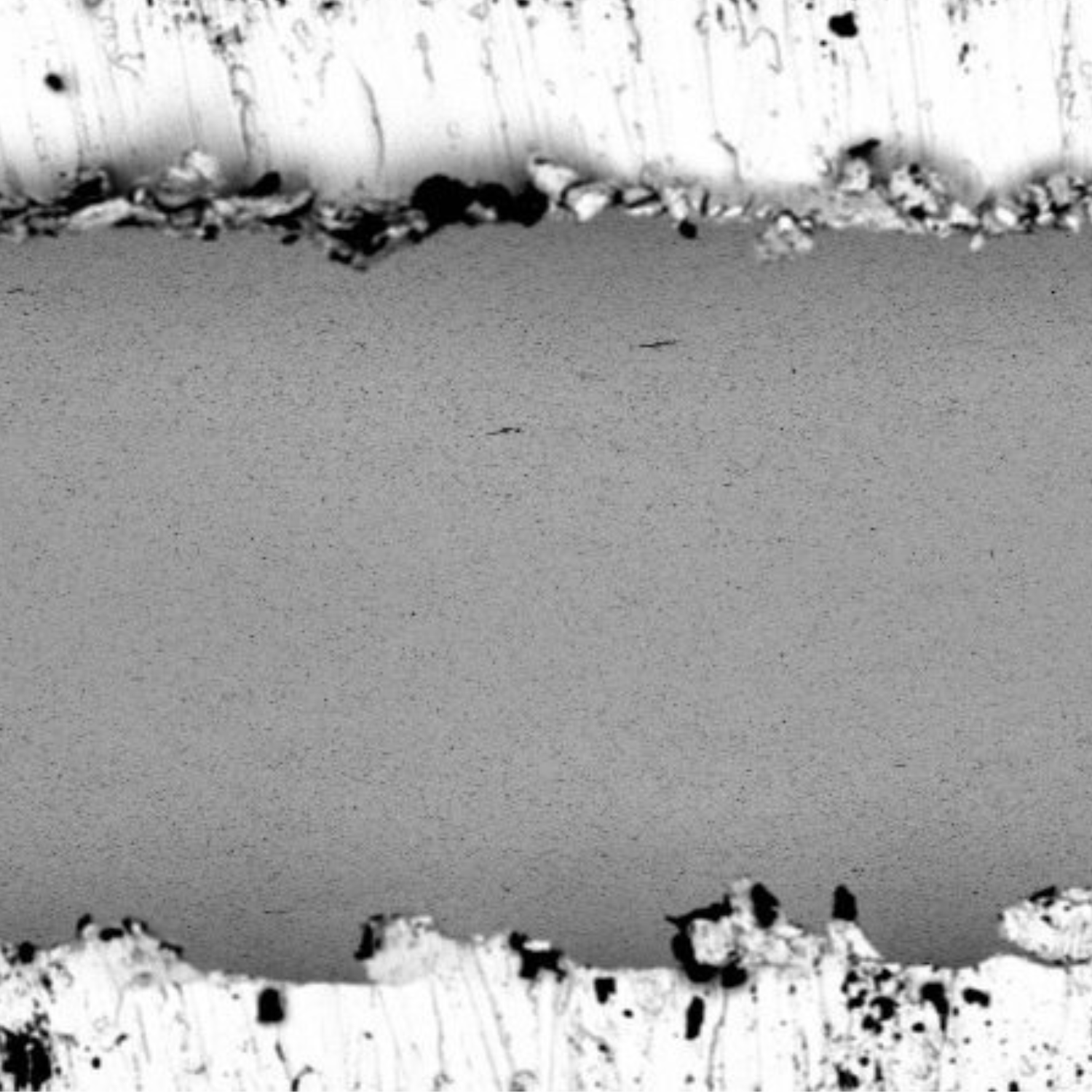

Taking advantage of the features that enable polishing of narrow holes and long lengths, the raw material is polished from the pipe state to minimize wrinkles and irregularities and achieve a mirror-like surface. In addition to contributing to quantitative analysis, it also reduces contamination. The improved repeatability also contributes to reliability and reduction of defective products, and increases the added value of the parts.

COVERAGE

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties |

Stainless steel (303,304,316,316L,etc) Titanium (Pure Ti,Ni-Ti,64Ti,etc) Aluminum (A5052,etc) Cobalt alloy (Elgiloy,Mp35N,etc) Nickel alloy (Inconel,Hastelloy,etc) Copper (cu,etc) Others (S 45C,SCM415,etc) *Please contact us for sizes and materials not listed. |

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties | Stainless steel, Titanium, Aluminum, Cobalt alloy, Nickel alloy, Copper, Others, *Please contact us for sizes and materials not listed. |

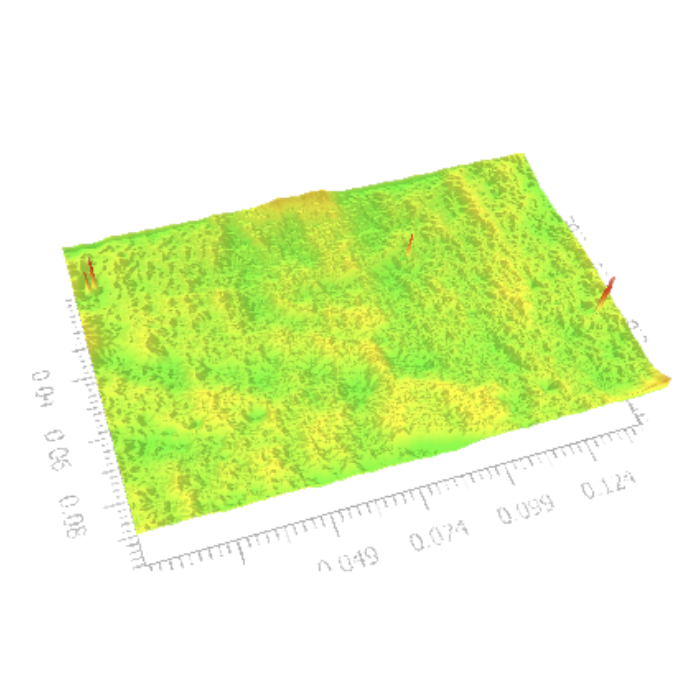

EVIDENCE

Initial value—

Ra0.736μm

—Achievement value

Ra0.07μm

ADVANTAGE

Point.01

Quality improvement and reduction of defective products

We have developed new equipment not for sale but for in-house mass production, which is even more reliable and stable. For those who suffer from manual operation and high variability, it can contribute to a reduction in defect rates and costs.

Point.02

Realization of desired surface roughness

Enables breakthroughs in technical aspects such as surface roughness and problem solving that were not feasible in-house. Problem solving enables new market development and device development, contributing to improved profitability.

Point.03

Realization of environmental measures

Nowadays, environmental considerations are an unavoidable issue. Measures taken during manufacturing are a particularly difficult issue, but in our case, polishing is done using only water and abrasives, a technology that has a very low environmental impact.

We have a solution for your “difficult processing”!

Let’s create new value that has never been seen before.