In fact, even if you do physically unreasonable processing, it will not lead to the good results you are looking for.

This is because the optimal polishing method changes depending on the material and shape. In fact, we have been able to do things that other companies couldn’t do. In particular, there is a difference in the polishing of medical equipment parts, 3D metal modeling products, and cemented carbide products.

Achievements in internal grinding of medical device parts A

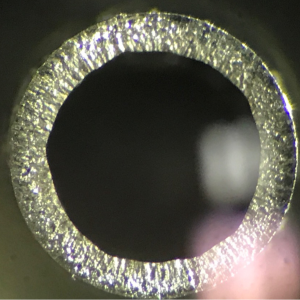

Metal pipe

Laser cut nickel titanium pipe

After fluid polishing, not only dross but also oxide film formed on the inner surface was removed and mirror polishing was achieved.

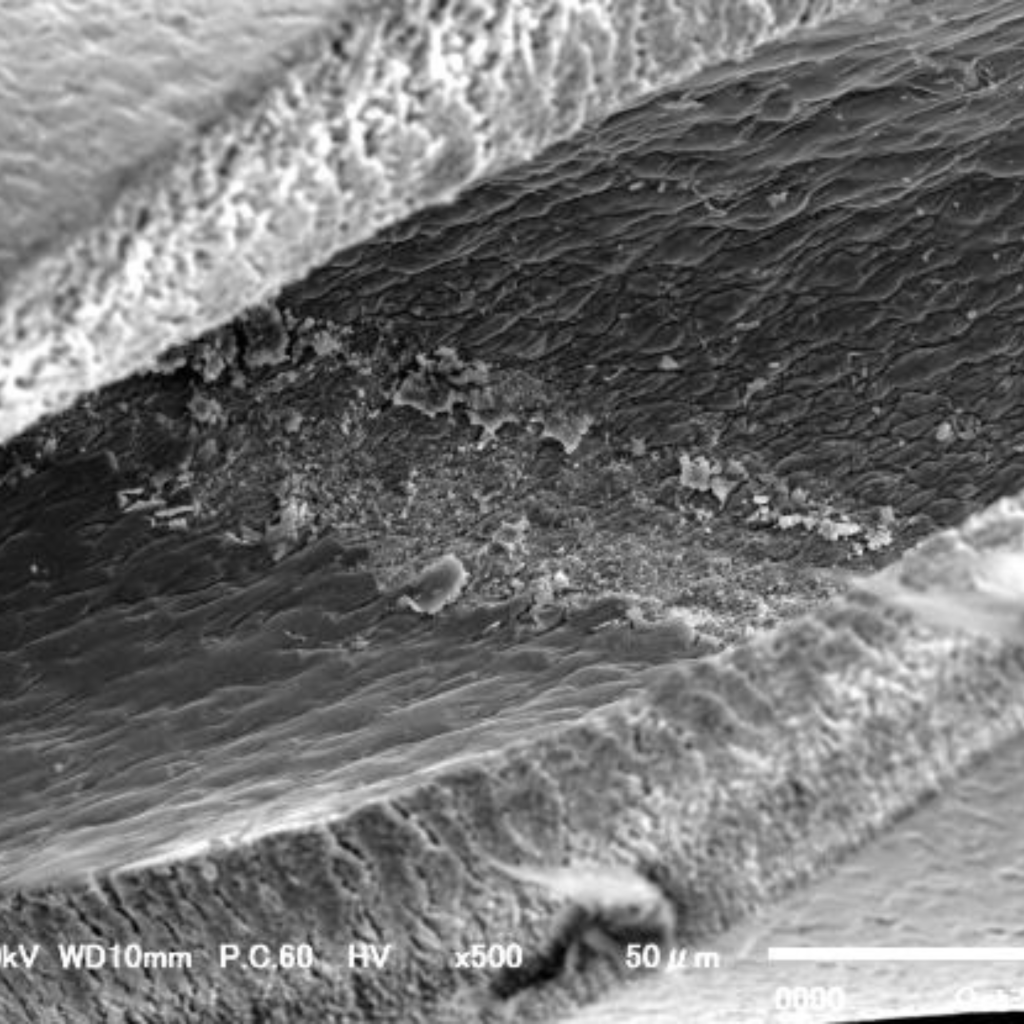

Before polishing

Dross and oxide film adhered after laser cutting

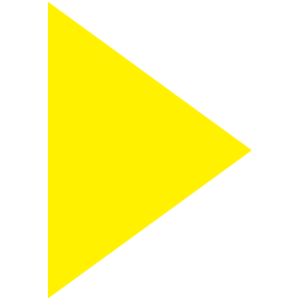

After polishing

Dross and oxide film have been removed.

Achievements in internal grinding of medical device parts B

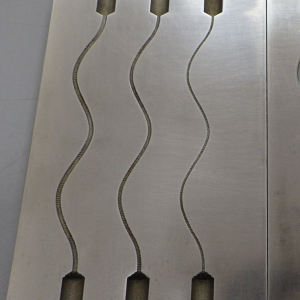

Metal pipe

Stent Nickel Titanium Pipe

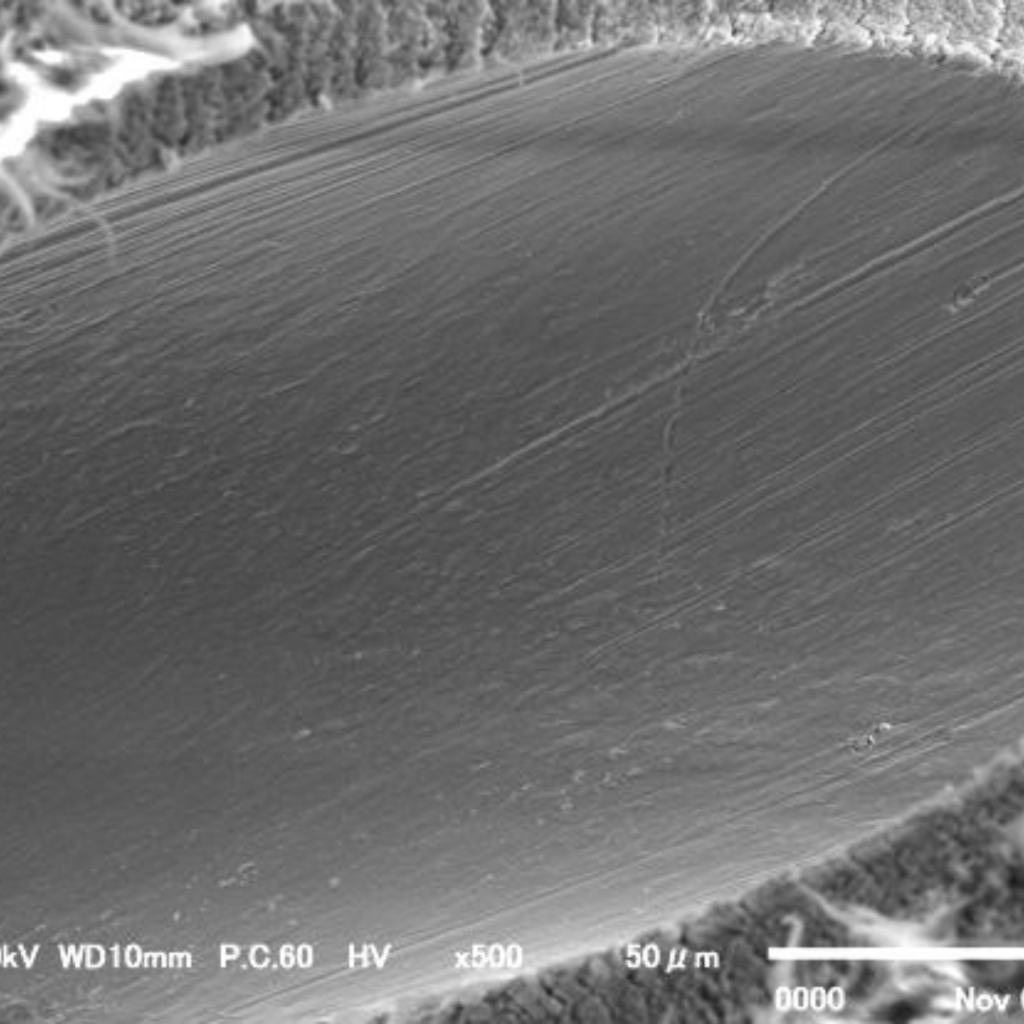

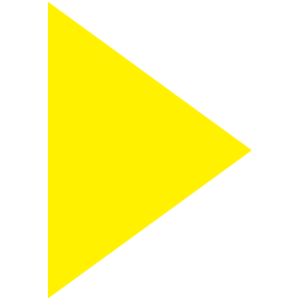

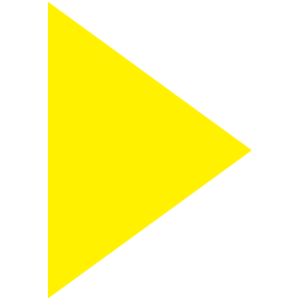

Before polishing

Burrs are showing.

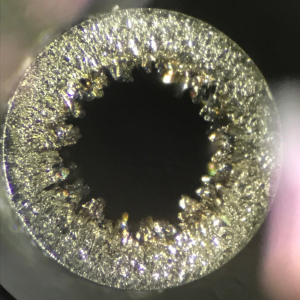

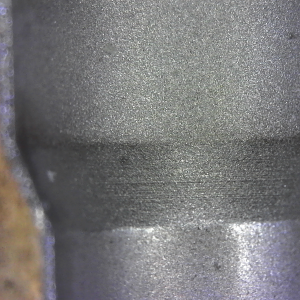

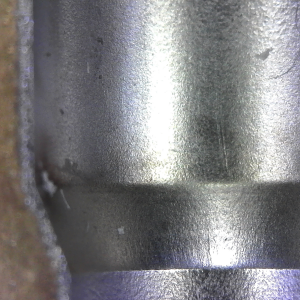

After polishing

Burrs are cleanly removed.

Reliable internal grinding results. Installed equipment in major companies.

We look forward to hearing from you.

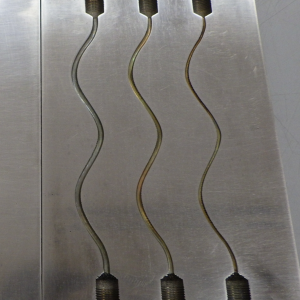

3D metal parts internal grinding results A

Metal Additive Manufactured Product

Small hole channel Polished sample: (left)φ2, (center)φ1.5, (right)φ1

Among the increasing use of AM products for “molds”, “precision parts” and “aerospace parts” in recent years, there are many products with fine holes. In particular, it is a sample product that can prove that it is possible to solve problems such as clogging removal and surface roughness improvement.

Before polishing

Ra10

After polishing

Ra0.13

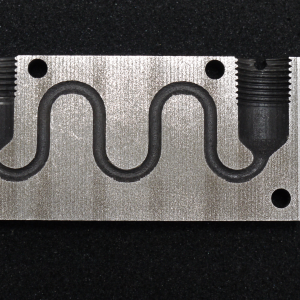

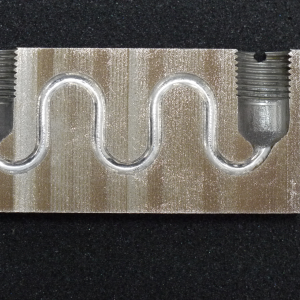

3D metal parts internal grinding results B

Metal Additive Manufactured Product

Cooling channel of the core mold Polished sample

Sample Provider:Shippo Moulds Co.,Ltd.

Many AM molds use maraging steel, and there have been many cases of mold cracks due to “rust” and “clogging.” As a countermeasure, the inside of the flow channel is polished to solve the problem of contamination and clogging. Periodic polishing is expected to maintain cooling performance and extend mold life.

Before polishing

Cooling channels for cored molds

After polishing:

Algovision

Polishing without losing shape.

After polishing:

Other companies

It has lost its shape.

3D metal parts internal grinding results C

Metal Additive Manufactured Product

Sample modeling provided:Castec Inc.

Many AM molds use maraging steel, and there have been many cases of mold cracks due to “rust” and “clogging.” As a countermeasure, the inside of the flow channel is polished to solve the problem of contamination and clogging. Periodic polishing is expected to maintain cooling performance and extend mold life.

Before polishing

After polishing

Before polishing

After polishing

Various industries, materials, and workpieces.

The problems are common. Let’s find a solution.

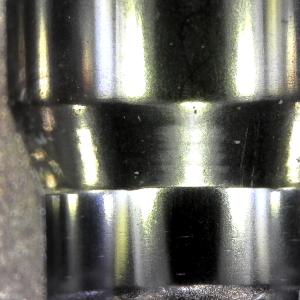

Achievements of internal polishing of cemented carbide molds A

Cemented Carbide Parts

Carbide forging dies

Samples provided:Japan Hardware Co., Ltd.

Mold polishing samples: (left) EDM, (center) EDM → fluid polishing, (right) fluid polishing → by hand

After EDM processing

EDM processing → Fluid polishing

Fluid polishing → Manual polishing

After EDM processing

EDM processing → Fluid polishing

Fluid polishing → Manual polishing

We offer free consultation for testing and equipment purchase.

We can help you solve your problems!