“CONCEPT”

The “power of flow” will change common sense.

Invisible inner walls, unreachable depths. Fluid penetrates into areas considered impossible with conventional polishing. The long interior of an ultrafine metal pipe, the mere tens of microns of a microhole nozzle, the delicate structure of a catheter or stent, the intricate molding surface of a 3D printer part–all of these can be finished uniformly with the power of fluid. All of them are finished uniformly with the power of fluid. Gently and reliably in places tools cannot reach. Polishing is now in the “fluid” era. A new standard for precision and safety begins here.

Sustainable internal polishing technology

No organic solvents or diamonds are used. Amidst the growing concerns about “environmental issues” and “cost issues,” we have developed a new technology that uses only water and abrasives. This is a sustainable polishing technology that fits the new era.

Simple and highly efficient polishing action

The machine and technical structure have been made as simple as possible in pursuit of “reproducibility,” “operability,” and “efficiency. It can be applied to various items from fine holes to long pipes, and multiple simultaneous polishing is possible.

Deburring and cleaning

It can also be used for post-processing fine burrs and surface cleaning. Needs are increasing in the fields of semiconductors, medical equipment, etc.It enables deburring and cleaning processes even in previously inaccessible locations and flow paths.

TECHNOLOGY COMPARISON

| item | Abrasive grain flow polishing | Magnetic fluid polishing | Fluid polishing |

|---|---|---|---|

| Polishing speed | △ | △ | ◎ |

| Microhole support | × | ◯ | ◯ |

| Material Adaptability | ◯ | △ | ◎ |

| environmental burden | small | medium | small |

ACHIEVEMENTS

Ra0.526

▶︎

Ra0.012μm

Request details/Improvement of internal roughness

Material/SUS316

Inner diameter/φ0.2

Ra3.629

▶︎

Ra0.104μm

Request: Improve surface roughness of cooling waterway and increase flow rate

Material/SUS420J2

Inner diameter/φ0.8

Ra5.075

▶︎

Ra0.076μm

Request: Improve surface roughness of cooling waterway and increase flow rate

Material/Al-Si alloy

Inner diameter/φ2.0

Medical Parts

Burr and unevenness removal

3DAM

Functionality UP

Semiconductor

Deburring and cleaning

Other

Crack removal

Medical device parts: Burr, unevenness removal, surface roughness improvement

3DAM parts: Increased functionality, improved surface roughness

Semiconductor parts: deburring, cleaning, surface roughness improvement

Other: Crack removal, cooling performance UP

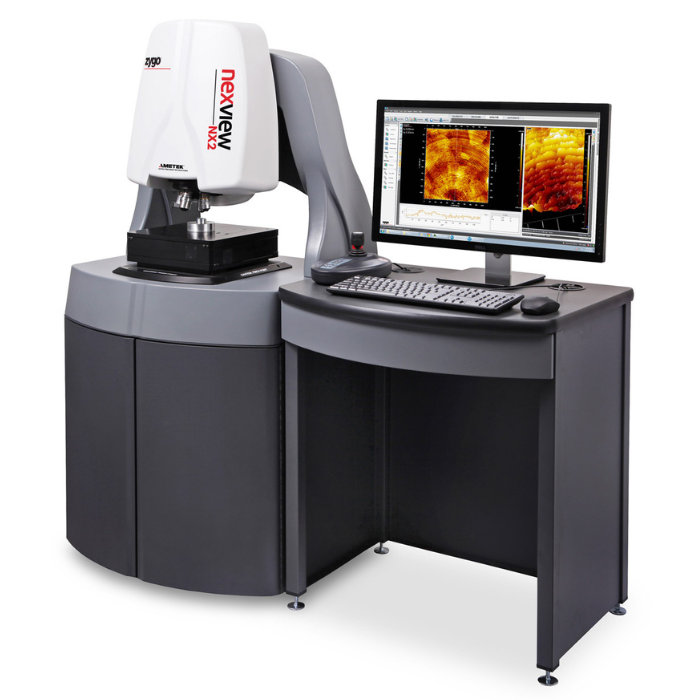

QUALITY

In order to provide and verify reliable data after prototyping and contract polishing, we contract with a reliable third-party public institution to perform data measurement.

In order to provide and verify reliable data after prototyping and contract polishing, we contract with a reliable third-party public institution to perform data measurement.

Surface roughness measurement equipment used

ZYGO Nexview NX2

ZYGO’s latest generation flagship product is a white interferometer with a state-of-the-art vertical scanning low coherence interferometer (CSI) profiler that combines ultra-high accuracy, advanced algorithms, versatility, and automation.

Contractor: Industrial Technology Center of Okayama Prefecture

As a core technical support organization for regional industries, the Industrial Technology Center is engaged in pioneering technological development in the mining and industrial fields and joint industry-academia-government research, and actively supports the creative activities of companies in the prefecture by providing technical consultation, research, and testing based on corporate needs.

SERVICE

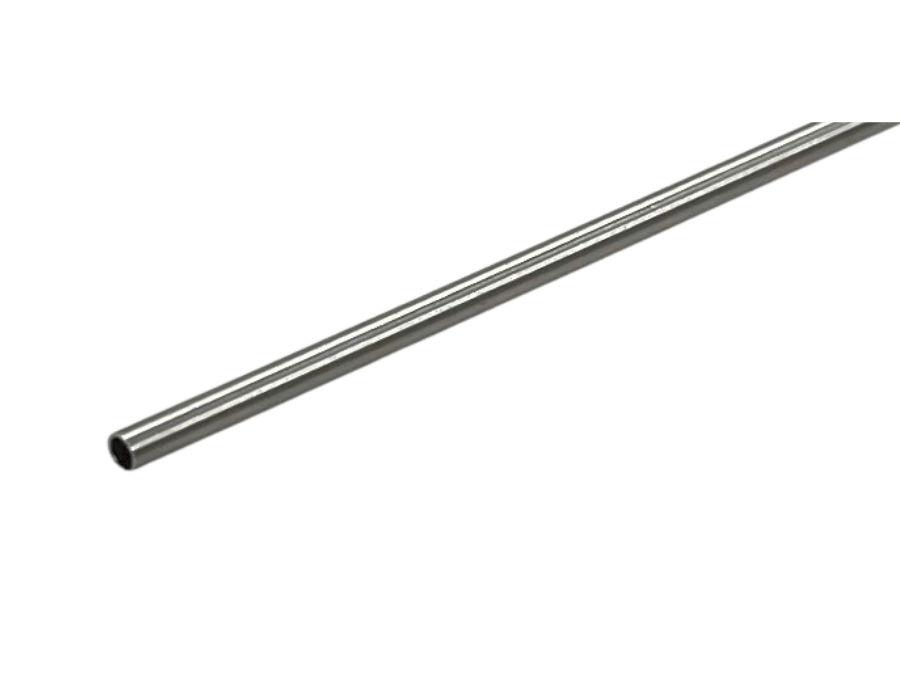

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties |

Stainless steel type (303,304,316,316L,SUS420J2,etc) Titanium type (Pure Ti,Ni-Ti,64Ti,etc) Aluminum type (A5052,ALSi10Mg,Duralumin,etc) Cobalt alloy type (Elgiloy,Mp35N,etc ) Nickel alloys(Inconel718,HastelloyX,etc) Copper alloys(cu,etc) Others(S45C,SCM415,SKD61,Maraging steel,Molybdenum,etc) *Please contact us for sizes and materials not listed |

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties | Stainless steel, Titanium, Aluminum, Cobalt alloy, Nickel alloy, Copper, Other, *Please contact us for sizes and materials not listed. |

FAQ

We have a solution for your “difficult processing”!

Let’s create new value that has never been seen before.