“CONCEPT”

That surface is our obsession.

The heart of semiconductor manufacturing equipment is always moving at the extreme limits. The slightest turbulence or wear that occurs inside it affects long-term operation and accuracy maintenance. Therefore, the accuracy of the inner surface is not just a finishing touch. It is the foundation that supports the stability, durability, and cleanliness of the entire equipment. We weave function and reliability into invisible surfaces. The accumulation of these elements will change the future results of our customers. It is the invisible polish that supports precision equipment.

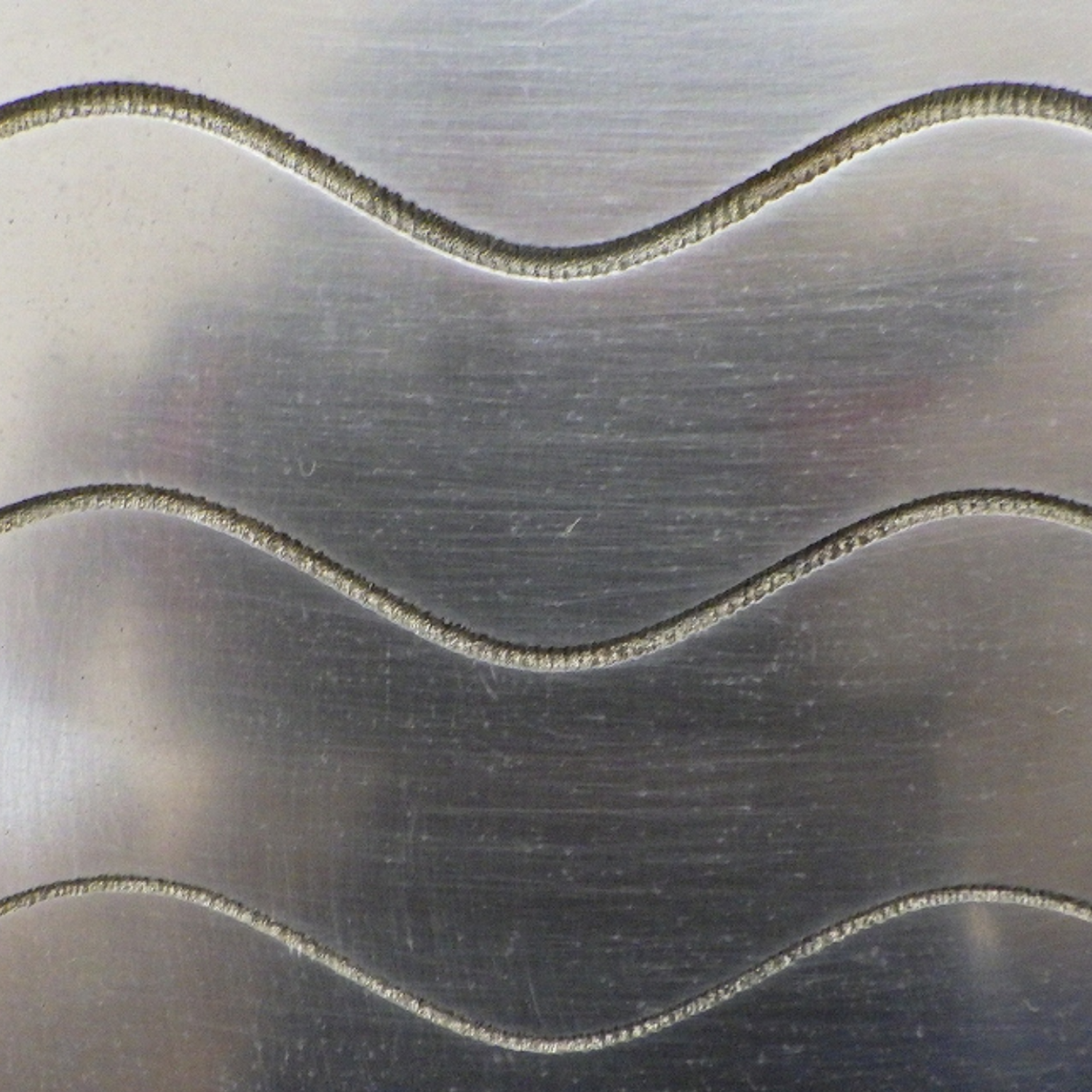

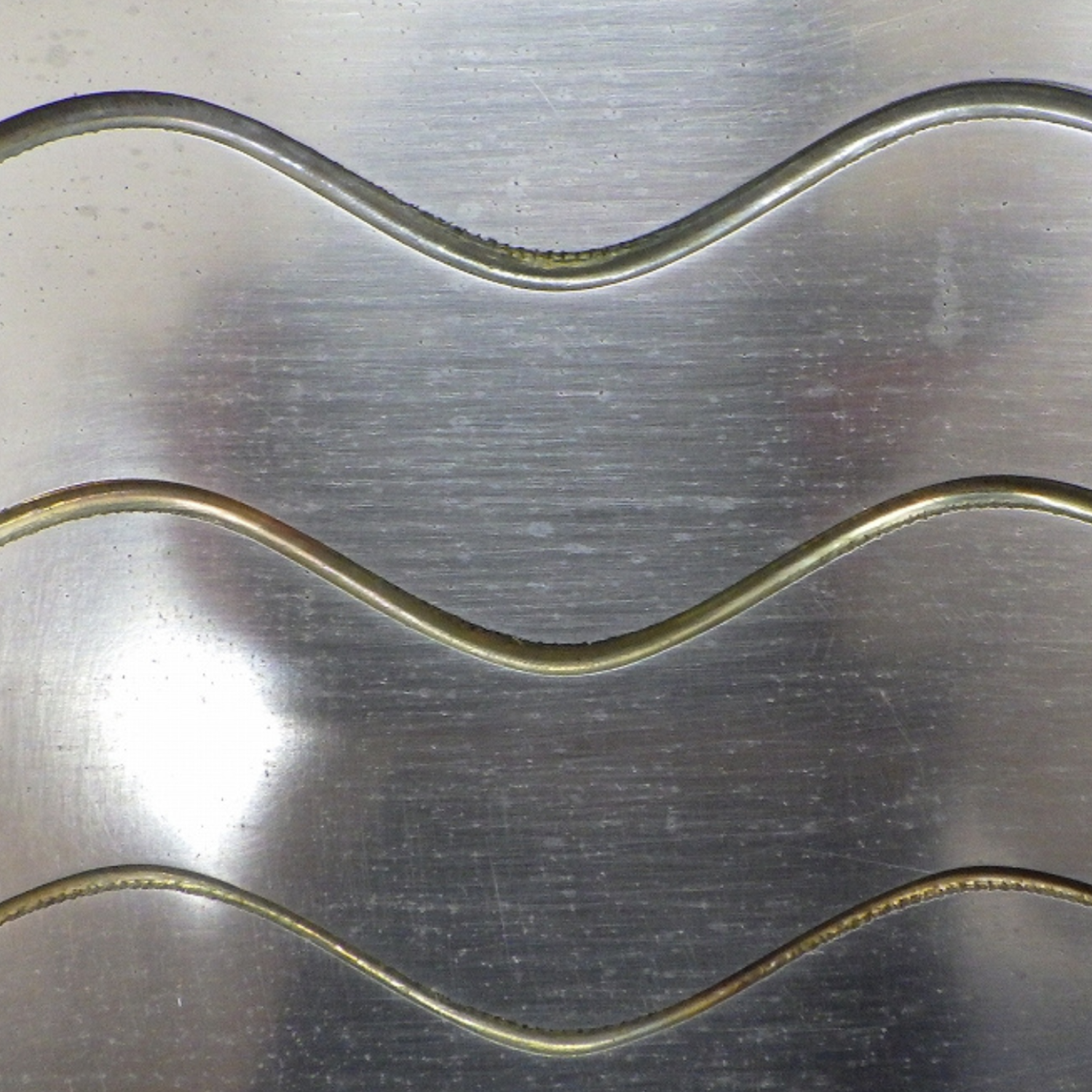

REMOVAL OF FINE BURRS

Fine burrs in semiconductor manufacturing equipment can cause particle generation, gas leakage, and component wear, which significantly reduce production efficiency and yield. Our micro-burr removal technology removes irregularities at levels that cannot be detected visually, resulting in a clean operating environment and extending the life of the equipment.

PURSUIT OF QUALITY

Taking advantage of the features that enable polishing of narrow holes and long lengths, the raw material is polished from the pipe state to minimize wrinkles and irregularities and achieve a mirror-like surface. In addition to contributing to quantitative analysis, it also reduces contamination. The improved repeatability also contributes to reliability and reduction of defective products, and increases the added value of the parts.

COVERAGE

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties |

Stainless steel (303,304,316,316L,SUS420J2,etc) Titanium (Pure Ti,Ni-Ti,64Ti,etc) Aluminum (ALSi10Mg,Duralumin,etc) Cobalt alloy (Elgiloy,Mp35N,etc) Nickel alloy (Inconel 718, Hastelloy X,etc) Copper alloys (cu,etc) Others (S45C,SCM415,SKD61,Maraging steel,Molybdenum,etc) *Please contact us for sizes and materials not listed |

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties | Stainless steel, Titanium, Aluminum, Cobalt alloy, Nickel alloy, Copper alloys, Others, *Please contact us for sizes and materials not listed |

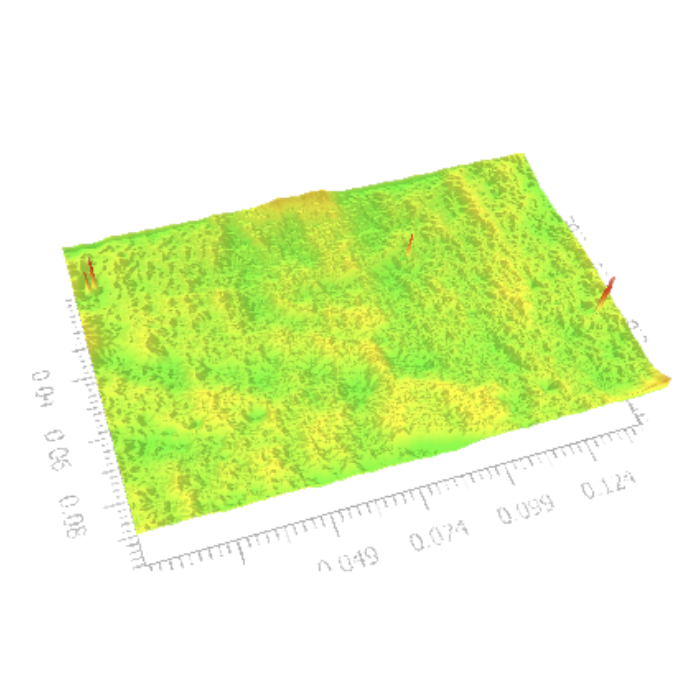

EVIDENCE

Initial value—

Ra10μm

—Achievement value

Ra0.13μm

ADVANTAGE

Point.01

Quality improvement and reduction of defective products

We have developed new equipment not for sale but for in-house mass production, which is even more reliable and stable. For those who suffer from manual operation and high variability, it can contribute to a reduction in defect rates and costs.

Point.02

Realization of desired surface roughness

Enables breakthroughs in technical aspects such as surface roughness and problem solving that were not feasible in-house. Problem solving enables new market development and device development, contributing to improved profitability.

Point.03

Realization of environmental measures

Nowadays, environmental considerations are an unavoidable issue. Measures taken during manufacturing are a particularly difficult issue, but in our case, polishing is done using only water and abrasives, a technology that has a very low environmental impact.

We have a solution for your “difficult processing”!

Let’s create new value that has never been seen before.