“CONCEPT”

Invisible precision, visible results.

Our work is not exactly outstanding. But we know this. We know that the “finish” of a metal is not just aesthetics, but function itself. For example, micron-level irregularities can disrupt heat flow, allow pressure to escape, and slightly deform components, eventually causing them to fail. In space, in thousands of degrees of heat, in tens of thousands of rotations. In such extreme conditions, polishing is the last and most important process to bring out 100% of the performance that a part should have. That is why we are so particular about precision, which is invisible to the eye. The result is the reliability that supports the stable flight of rockets, the operating rate of plants, and human lives. Grinding is what makes the results possible. Invisible precision, visible results.

REMOVAL OF MICROCRACKS

In the aerospace industry, the slightest microcrack can lead to catastrophic failure in extreme environments. Our precision polishing technology removes minute cracks that lie beneath the surface, dramatically improving structural reliability. We support reliable quality even under high loads and high vibrations from invisible parts.

PURSUIT OF QUALITY

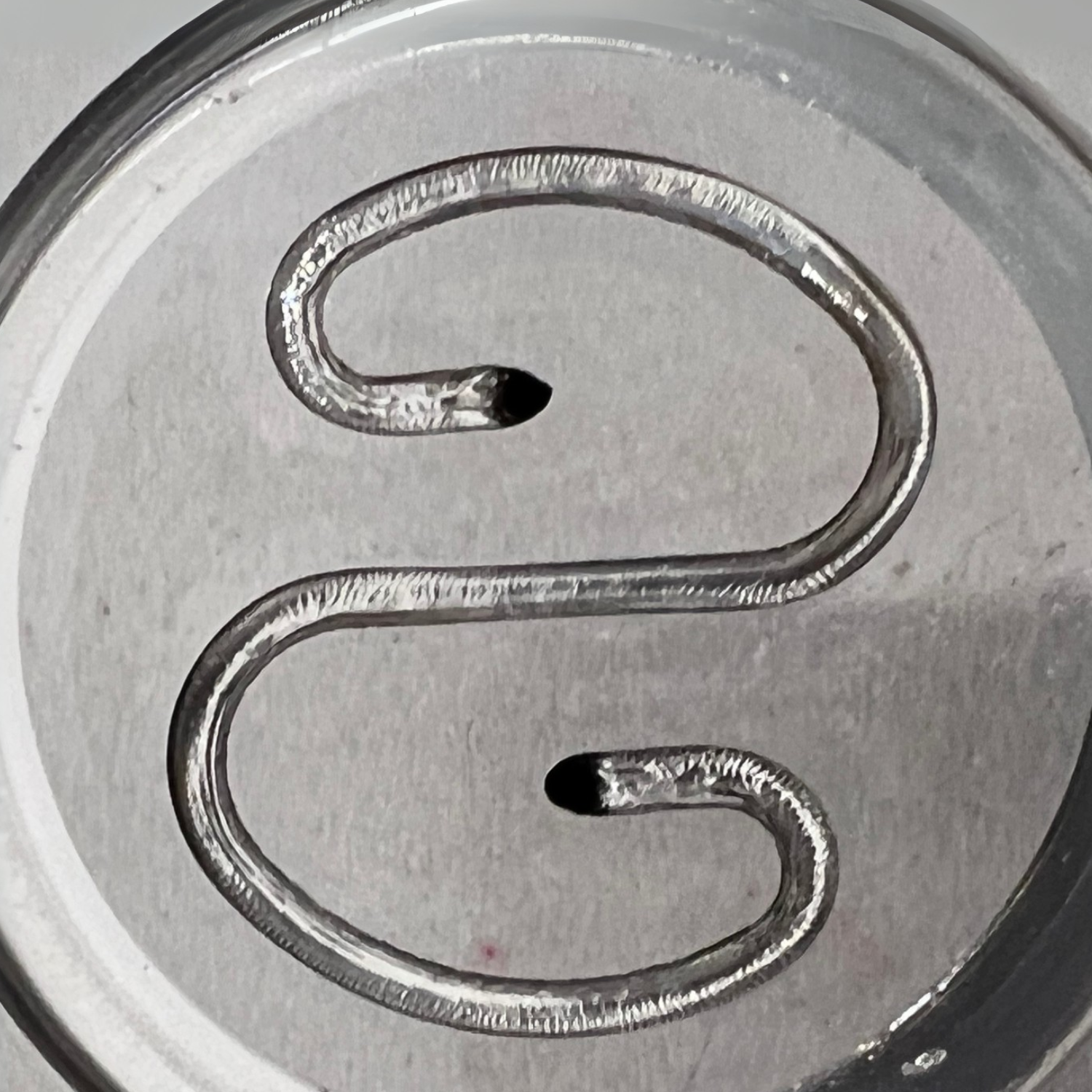

Our internal surface polishing technology reduces wear, suppresses turbulence, and prevents foreign matter adhesion in fuel and cooling channels and inside precision mechanisms by controlling surface roughness in microns. This finish directly improves thermal efficiency, fuel efficiency, and service life, resulting in improved performance. We understand that the true value of technology is tested in the parts that cannot be seen, and we meet those demands.

COVERAGE

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties |

Stainless steel (303,304,316,316L,SUS420J2,etc) Titanium (Pure Ti,Ni-Ti,64Ti,etc) Aluminum (ALSi10Mg,Duralumin,etc) Cobalt alloy (Elgiloy,Mp35N,etc) Nickel alloy (Inconel 718, Hastelloy X,etc) Copper alloys (cu,etc) Others (S45C,SCM415,SKD61,Maraging steel,Molybdenum,etc) *Please contact us for sizes and materials not listed. |

| inside diameter | φ0.1~φ5.0 |

|---|---|

| length | ~2000㎜ |

| material properties | Stainless steel, Titanium, Aluminum, Cobalt alloy, Nickel alloy, Copper alloys, Others, *Please contact us for sizes and materials not listed. |

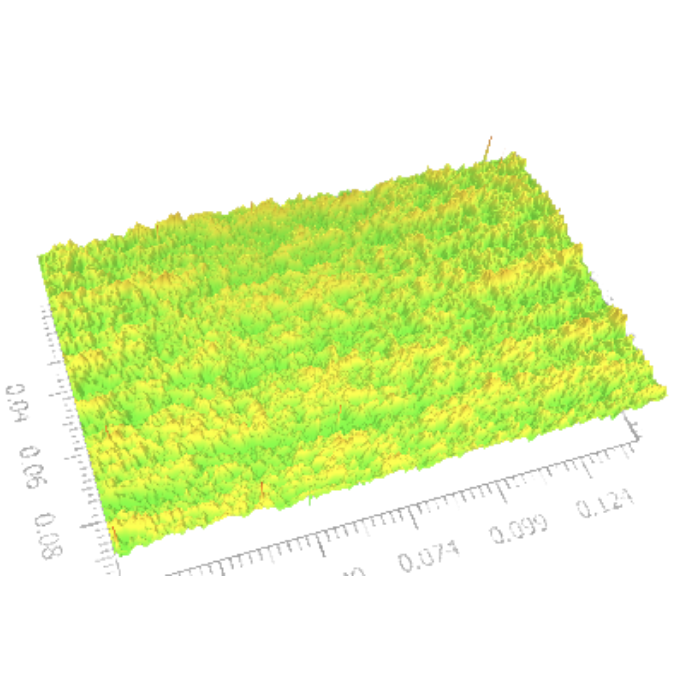

EVIDENCE

Initial value—

Rz100μm

—Achievement value

Rz1.6μm

ADVANTAGE

Point.01

Quality improvement and reduction of defective products

We have developed new equipment not for sale but for in-house mass production, which is even more reliable and stable. For those who suffer from manual operation and high variability, it can contribute to a reduction in defect rates and costs.

Point.02

Realization of desired surface roughness

Enables breakthroughs in technical aspects such as surface roughness and problem solving that were not feasible in-house. Problem solving enables new market development and device development, contributing to improved profitability.

Point.03

Realization of environmental measures

Nowadays, environmental considerations are an unavoidable issue. Measures taken during manufacturing are a particularly difficult issue, but in our case, polishing is done using only water and abrasives, a technology that has a very low environmental impact.

We have a solution for your “difficult processing”!

Let’s create new value that has never been seen before.